Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

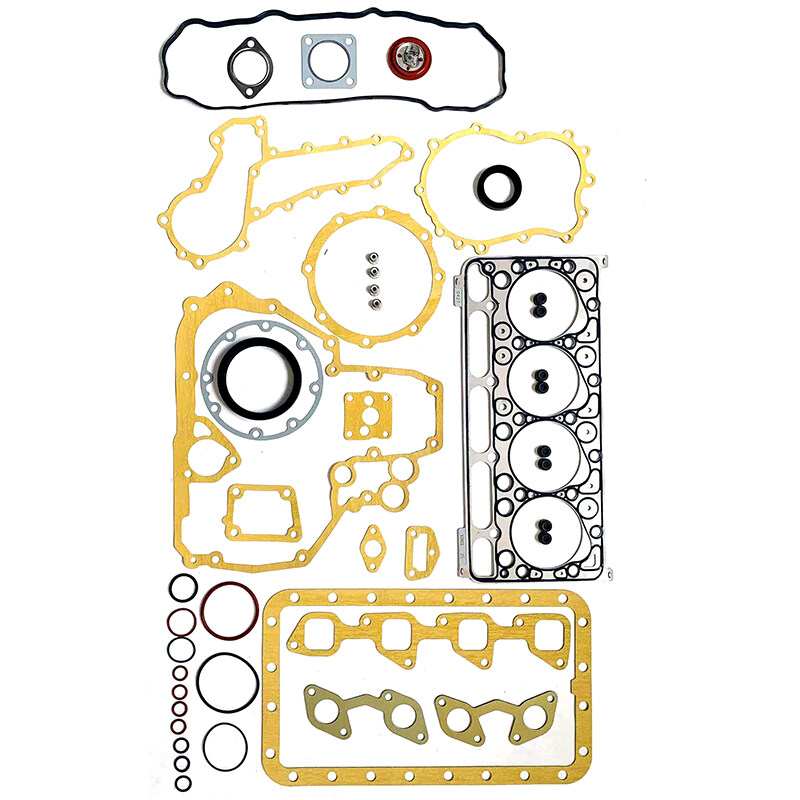

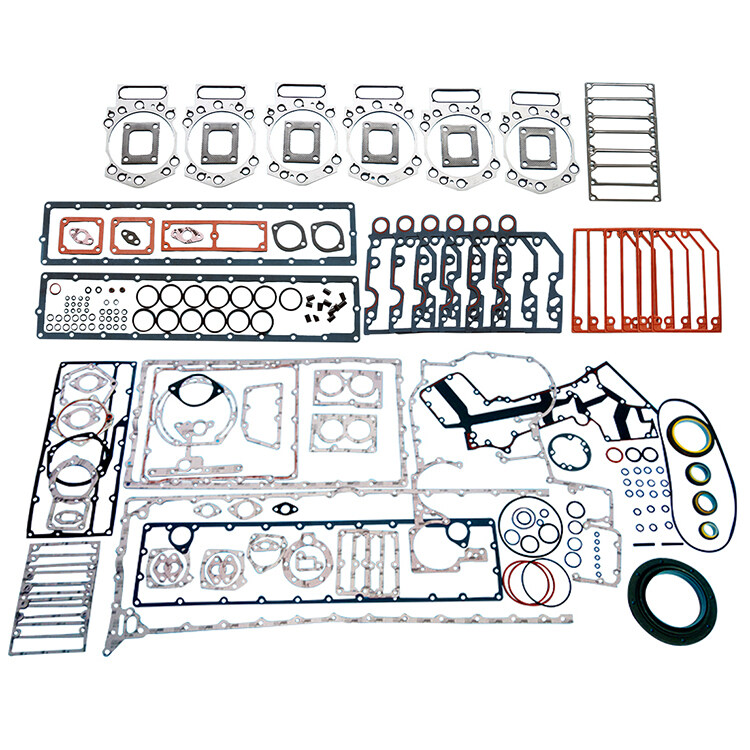

4D87 Engine Full Gasket Set

The Kubota 4D87 Engine Full Gasket Set is a comprehensive package of gaskets and seals designed to provide a complete sealing solution for the Kubota 4D87 engine. Kubota is a well-known manufacturer of engines, particularly in the agricultural and construction equipment industries.

The full gasket set typically includes various gaskets and seals required for the engine, ensuring proper sealing and preventing leaks. Here's what you can expect to find in a Kubota 4D87 Engine Full Gasket Set:

-

Cylinder Head Gasket: The cylinder head gasket is a critical component, providing a seal between the engine block and cylinder head. It ensures proper compression, prevents the escape of combustion gases, and separates coolant and oil passages.

-

Intake and Exhaust Manifold Gaskets: These gaskets seal the junctions between the intake and exhaust manifolds and the cylinder head. They help maintain proper air and exhaust gas flow.

-

Valve Stem Seals: Valve stem seals prevent oil from entering the combustion chamber through the valve guides and ensure the proper lubrication of the valve stems.

-

Timing Cover Gasket: The timing cover gasket seals the front of the engine and is essential for keeping the timing components protected and oil contained.

-

Oil Pan Gasket: The oil pan gasket prevents oil leaks at the bottom of the engine and keeps the engine oil contained in the oil pan.

-

Rear Main Seal: The rear main seal is located at the back of the engine and prevents oil leaks where the crankshaft exits the engine block.

-

Various Seals and O-Rings: Full gasket sets may also include various seals and o-rings, such as camshaft seals, front and rear crankshaft seals, and other smaller seals needed for specific engine components.

Product Parameter:

|

Product Name |

Engine Full Gasket Set |

|

Application |

Machinery Repair Shops, Construction Works, Energy & Mining |

|

Engine Number |

4D87 |

|

Size |

STD |

|

Material |

High Quality Metal and Rubber |

|

Warranty |

6 Months |

|

Condition |

100% Brand-new |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

Kubota |

|

Packing |

Neutral Packing |

The full gasket set is designed with a one-piece construction, making it easy to install and remove, reducing maintenance time and cost. The gasket set is manufactured using high-quality metal and rubber materials that are highly resistant to high temperatures, ensuring stable performance in even the most extreme working conditions.

Efficiently Prevent Leakage From Liquids and Gas:

The full gasket set is a critical component in modern engines, designed to prevent leaks and ensure optimal performance and reliability. The gasket set is manufactured using a multi-layered design that effectively prevents the leakage of liquids and gases, improving the engine’s reliability and stability. The multi-layered structure of the gasket set provides a high level of sealing performance, ensuring that the engine operates at peak efficiency and performance. The gasket set’s multi-layered design also helps to protect the engine from damage and wear, extending its service life and reducing the need for frequent repairs and replacements.

Economic and Practical:

The gasket set is manufactured using high-quality materials that are highly resistant to wear and tear, ensuring a long service life and reducing the need for frequent repairs and replacements. The use of high-quality materials in the gasket set’s construction also helps to reduce maintenance costs and replacement frequency, making it an economical and practical choice for engine owners. The gasket set’s long service life and durability ensure that the engine operates at peak efficiency and performance, reducing the risk of breakdowns and downtime. Additionally, the gasket set’s high-quality construction helps to reduce emissions, ensuring that the engine meets environmental regulations and standards.

FAQ:

Q1: What kind of products do you produce?

Re: We mainly produce the engine parts, like piston, piston ring, cylinder liner, engine valve, engine guide, head gasket, full gasket set, etc..

Q2: Do you support OEM or ODM?

Re: We support.

Q3: Can I purchase with only 1 sample?

Re: You can do that if the products that you need is in stock.

What is Full Gasket Set

A cylinder gasket is an object that seals the oil and gas inside the cylinder. Commonly used cylinder gaskets include asbestos (non-asbestos) rubber compound gaskets, metal clad (copper clad) gaskets, composite coated gaskets, metal compound gaskets, metal rubber ring gaskets and other types.

The Role of Full Gasket Set

The sealing technology of the cylinder gasket set plays a pivotal role in assessing the overall performance of the engine, reflecting the comprehensive technical level of the engine.

Therefore the seal material and sealing technology are particularly important. The sealing technology of the engine has to take into account high temperature, high pressure, high power and various media such as lubricating oil, antifreeze and gas. This places higher demands on the sealing of oil and water holes.

Product Features

Rubber cylinder gaskets for engines operate at high temperatures, high pressures, high powers and in various media such as lubricating oil, antifreeze and gases, which place high demands on the material of the oil and water bore.

Metal rubber cylinder gaskets with oil and water holes are mainly made of fluoroelastomer and silicone rubber to meet the requirements. Different structures of the metal rubber cylinder gasket can choose different kinds of rubber.

Single layer one rubber ring material can choose peroxide vulcanized fluorine rubber, bisphenol vulcanized fluorine rubber and oil resistant silicone. Single riveted rubber cylinder gasket, multi-layer rubber cylinder gasket oil hole material can choose bisphenol vulcanized fluorine rubber or oil silicone, peroxide vulcanized fluorine rubber is expensive, can not choose. Water hole material can choose ordinary silicone rubber or oil-resistant silicone rubber, peroxide vulcanized fluorine rubber is expensive, can not be selected.

Common Types

According to the different characteristics of raw materials, cylinder gaskets can be divided into: copper plate cylinder gasket, composite plate cylinder gasket and asbestos cylinder gasket. DAI-EL is coated with fluoroelastomer DAI-EL, which can withstand repeated heating and heat resistance, and has excellent oil resistance and sealing properties.

What is the Metal Rubber Cylinder Gasket Set

Metal rubber cylinder gaskets are structurally divided into single-layer one-piece rubber cylinder gaskets, single-layer riveted rubber cylinder gaskets, multi-layer clip rubber cylinder gaskets, etc.

The metal rubber cylinder gasket production method mainly has the whole piece of vulcanization molding and rubber ring vulcanization molding and then with the metal skeleton combination method. The whole piece of vulcanization refers to the use of injection or moulding method of oil and water hole rubber cylinder gasket injection vulcanization. This method is used for single-piece rubber cylinder gaskets.

Vulcanized rubber cylinder gasket and metal frame combination method is the use of injection or moulding method with or without the skeleton of the oil and water cylinder gasket, and then with the metal skeleton of the way to join up. Single layer riveted rubber cylinder gasket and multi-layer clamp rubber cylinder gasket using this method.

For more information about 4D87 Full Gasket Set, please kindly contact us at any time, we are glad to answer for you. If you want to order in quantity, hope that we will be your best choice.