Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

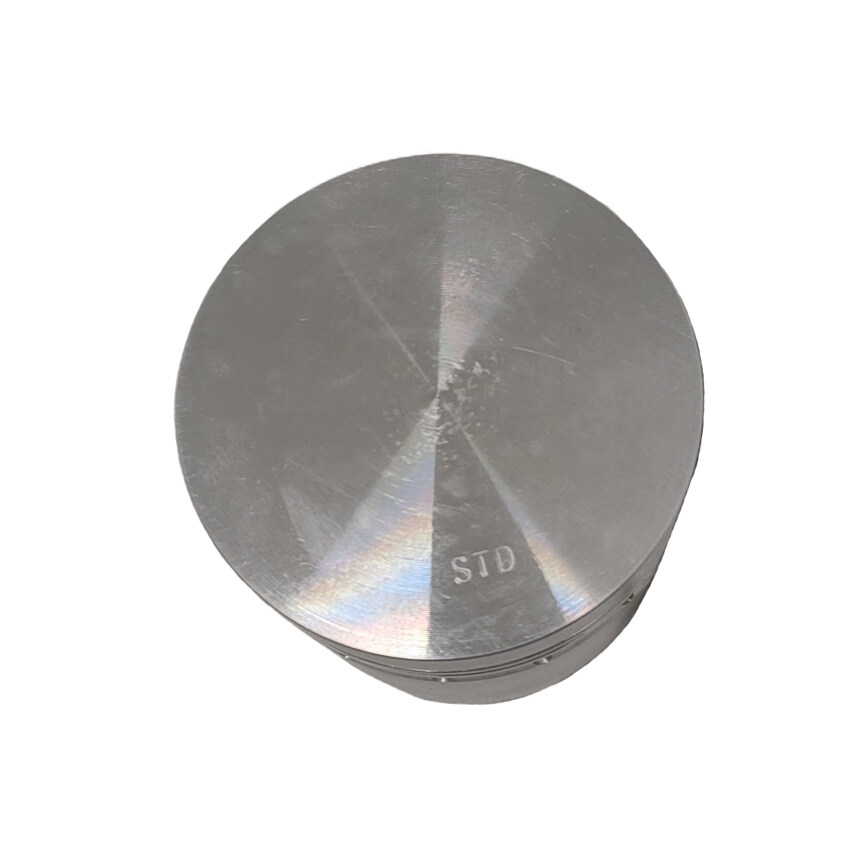

V1502 Diesel Engine Piston Set

The V1502 Diesel Engine Piston Set is a crucial component used in the Kubota V1502 engine, which is commonly found in various compact industrial and agricultural machinery. The piston set is designed to withstand the demands of diesel engine operation and contributes to efficient power generation

Features and functions of the V1502 Diesel Engine Piston Set:

-

Materials and Construction: The pistons in the V1502 engine piston set are typically constructed from high-strength materials, such as aluminum alloy or cast iron. These materials are chosen for their durability and heat resistance, ensuring they can withstand the high temperatures and pressures generated during combustion.

-

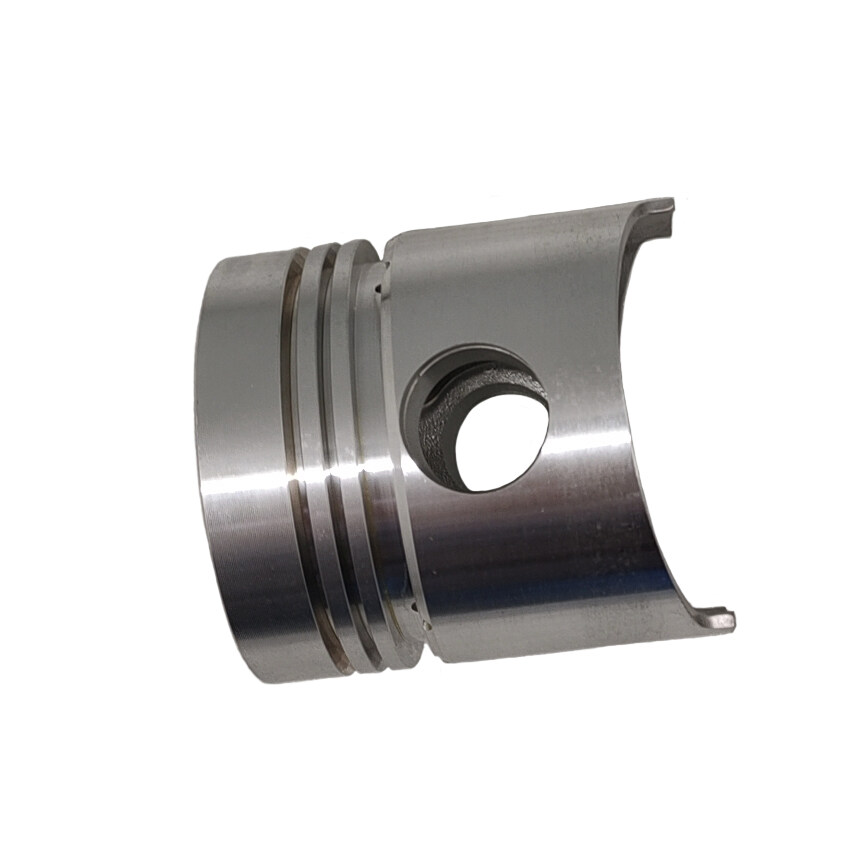

Ring Grooves: Each piston in the set includes grooves for piston rings. These rings are responsible for creating a seal between the piston and the cylinder walls. Proper sealing prevents the escape of combustion gases, maintains compression, and reduces oil consumption.

-

Crown: The piston crown, located at the top, is designed to withstand the high-temperature environment of the combustion process. It must be heat-resistant and structurally robust.

-

Skirt: The piston skirt is the lower portion that makes contact with the cylinder walls. It helps guide the piston's movement within the cylinder and provides stability during engine operation.

-

Wrist Pin or Piston Pin: The wrist pin, also known as the piston pin, connects the piston to the connecting rod. It allows the piston to pivot and transfers the linear motion of the connecting rod into the rotary motion of the crankshaft.

-

Cooling Features: Some diesel engine pistons, particularly in high-performance engines, may incorporate cooling features, such as oil jets or internal cooling channels, to manage the piston's temperature and prevent overheating.

-

Balanced Weight: Properly balanced piston design ensures that the reciprocating mass is evenly distributed, reducing vibrations and minimizing wear on engine components.

The V1502 Diesel Engine Piston Set is engineered for durability, precise fit, and efficient power generation. Regular maintenance and inspection are essential to ensure that the pistons are in good condition, as wear or damage can affect engine performance and efficiency.

The diesel engine piston set is a crucial component that has been specifically engineered to enhance engine performance. Constructed from premium materials, the piston set is designed to withstand high temperatures and pressures, ensuring optimal engine performance and longevity. The piston set’s distinctive design guarantees an exact match with other engine components, thereby minimizing the time required for installation and repair.

The Exquisite Craftsmanship Decreases the Friction and Damage with Cylinder:

Using precision machining technology ensures that each piston’s surface finish and flatness meet strict standards. This precision machining process reduces friction and wear between the piston and cylinder, thereby extending the engine’s service life. The precision machining process involves using advanced equipment and techniques to ensure that each piston’s surface is smooth and flat, with no roughness or irregularities that could cause excessive wear or damage to the cylinder walls. The result is a piston set that fits precisely into the engine’s cylinder, reducing friction and wear and extending the engine’s life. Additionally, the precision machining process ensures that each piston is of consistent quality, with no variations in size or shape that could affect engine performance.

Premium-grade Material Enhance the Engine’s Performance and Efficiency:

The engine diesel piston set is crafted from premium-grade materials that possess exceptional strength and durability, enabling them to withstand the rigors of high-pressure and high-temperature environments. The materials used in the manufacturing process are meticulously selected to ensure that they can endure the extreme conditions of the engine’s operation without succumbing to wear, corrosion, or other forms of degradation. The use of such high-strength materials also allows the piston set to withstand the stresses and strains of high-speed operation, reducing the risk of failure or damage to the engine. Moreover, the superior quality of these materials enables the piston set to operate at elevated temperatures and pressures, thereby enhancing the engine’s performance and efficiency. The material can be also customized if you need!

Product Parameter:

|

Product Name |

Engine Piston Set |

|

Application |

Excavator, Loader, Bulldozer, Forklift, Trucks, Buses and Others |

|

Engine Number |

V1502 |

|

Size |

STD |

|

Year |

1980-2001 |

|

Condition |

100% Brand-new |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

Kubota |

|

Packing |

Neutral Packing |

Product Structure:

Engine components today need to be tough for longevity and lightweight to improve efficiency, which means all pistons are some form of aluminum alloy. But back in the dawn of the horseless carriage era pistons were made of cast iron because they were very long wearing, and resistant to heat that could quickly melt aluminum. As metallurgy progressed, and temperatures were kept under better control through more efficient design, the lightness of aluminum quickly won out, and allowed much higher RPM to be achieved.

The piston rings continued to be made out of cast iron and steel alloys, because of their higher spring constant. The ring package usually comprises, from top to bottom, a compression ring, a wiper ring and an oil ring all made from cast iron or steel.

The compression ring seals the gap between piston and cylinder. The second, wiper ring, contributes to the compression as well as wiping excess oil off the walls of the cylinder as the piston moves downward. The oil ring, is actually made of 2 rings and a spreader in most motors, and also wipes oil from the cylinder wall, then allows it to drain back through small holes in the ring land. But over time the rings can wear and lose their elasticity, allowing oil from the crankcase to move into the combustion chamber. Excessive oil consumption and bluish smoke from the tailpipes usually indicates piston ring wear.

Piston Clearance:

Usually, the piston is slightly smaller in diameter than the cylinder bore. Therefore, the space between it and the cylinder wall is called piston-clearance. This clearance is necessary for the following reasons.

It provides a space for a film of lubricant to reduce friction between the piston and cylinder wall.

It prevents seizures. Piston and cylinder block expand due to very high temperatures. However, the system cools the cylinder better than the piston. Hence, there must be sufficient clearance between them for it to expand.

Without sufficient clearance, it will be impossible for the piston to operate in the cylinder, reducing its efficiency.

The amount of clearance depends upon the cylinder bore’s size and the piston’s material. But, usually, it is 0.025mm to 0.100mm. In operation, a film of lubricating oil fills up the clearance space. Therefore, technicians must maintain proper clearance between piston and cylinder while overhauling the engine.

Effects of Clearance:

If the clearance is too small, it will increase the friction, resulting in a loss of power. If the clearance is too much, it will result in ‘piston slapping.’ It means sudden shaking of the piston when it goes downward in the power stroke, causing a distinct noise. As the engine warms up, this clearance reduces, and the noise usually disappears. Manufacturers use special alloys and different designs to reduce the slap.

For more information about V1502 piston, please kindly contact us at any time, we are glad to answer for you. If you want to order in quantity, hope that we will be your best choice.